Hello, everyone! I have been dead for a long time on here. I'm back for today because I couldn't keep this a secret any longer. THIS PROJECT IS ALMOST COMPLETE, this is not a full write-up. It loads and fires but has a bad seal. I can fix that but I don't have time--I haven't touched the project or even the tools in many months. That's why I'm just gonna show you my thing and let you do what you want with it.

No official name but let's call it the Sex Pistol for now. First person to perfect it gets to rename it. But do you really want to?

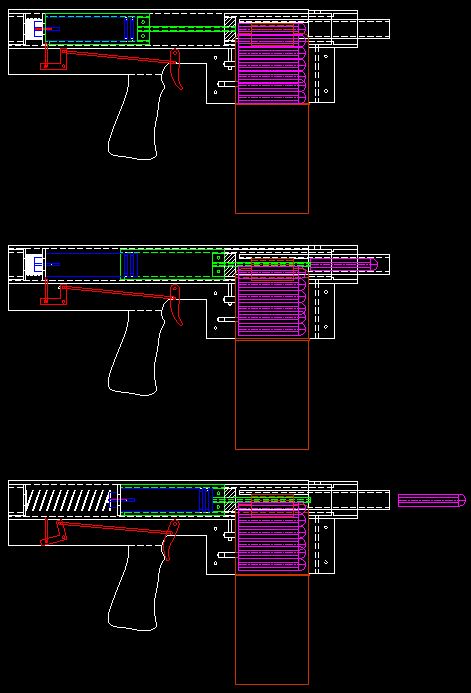

![gun one.jpg]()

![gun two.jpg]()

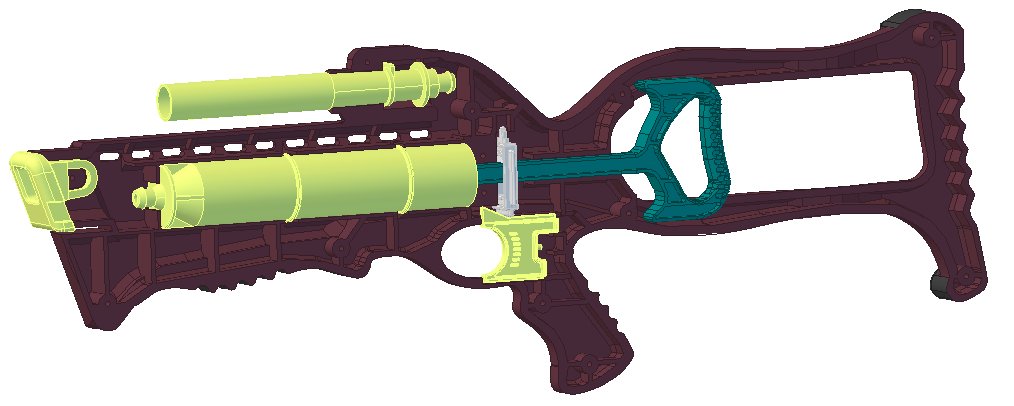

The biggest inspiration was the

Multiple Orgasm, by makeitgo. The day I saw that thread was the day I finally had what I needed to make the SP. Let me tell you, I had some far out ideas about how to make a mag-fed pistol, none of them realistic.

The Sex Pistol is just a like a real pistol. You can load a magazine in the handle, cock the slide back, slide returns forward, you pull the trigger, dart leaves the barrel. It's got some weight to it, feels good in the hand, and is 12" long.

ANIMATION of sexy 1st design

Of course, nothing stays the same. I've changed some moving parts when I found out that the real world isn't the same as the 3D model world.

VIDEO of sexy man cocking and dry-firing the Sex Pistol

The best change I made was the way I made the handle and the magazines. For the handle, I used a heat gun to soften the 1-1/4" PVC and then shoved two lengths of 1/2" PVC inside, side by side, to "spread" it from the inside. While it cooled, I pressed it between two wooden boards to flatten the sides a bit. The result is so comfy and strong. For the magazines, you can do the same with 1" thin-wall PVC, with two lengths of 1/2" CPVC inside--OR you can shove the softened 1" pipe inside the handle you already made. As it cools, wiggle it around and slide it in and out--this will keep it from hardening and getting stuck. You can cool the pipe faster by spraying water on it. ALL OF THIS SHOULD BE DONE IN A VENTILATED AREA--some, like Captain Slug, would suggest that you also wear some kind of respiratory protection.

The coolest change is the way the slide can be locked in the cocked position to allow for easy magazine swap. This came about from a design change where the magazine would be "closed" at the top which wouldn't allow the dart-retainer-lips-things to spread around the bolt. I like this feature, even if the magazine lips are open and allow the bolt to pass through. You wouldn't need this slide-lock if you decide not to add the slide return spring, which is on the barrel and pushes the slide forward after being cocked. But why wouldn't you want that?! It's so cool!

VIDEO of sexy man poppin' and lockin'

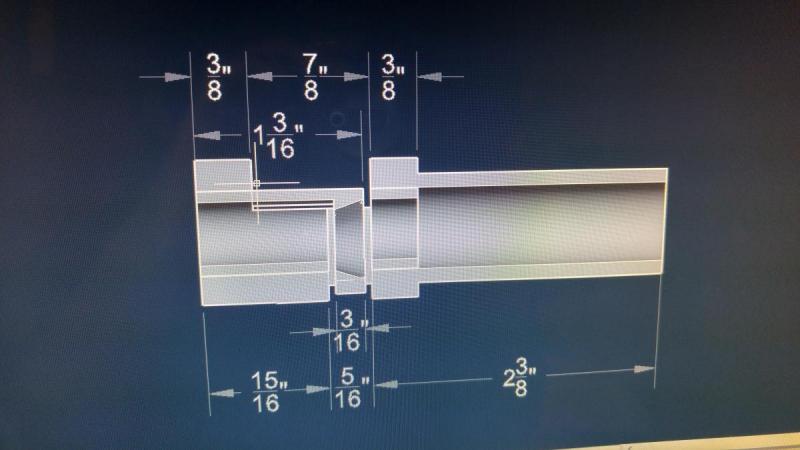

The most difficult change was the damn "mobile" catch and trigger assembly. The first reason for this change was that the plunger and catch would slide back in the plunger tube, instead of firing, when the trigger was pulled. Only way to stop that was to hold the slide forward with your free hand, which is dumb. The solution was to come up with a trigger that pushed up or forward or both. I went with the one in the middle on the left side of the animated image linked below. The trigger is a length of 1/2" CPVC, with a hole cut out to allow for the gray flexible trigger-catch-pusher-thing. The gray strip is just thin metal with a rounded nub of plastic glued on it.

ANIMATION of trigger designs

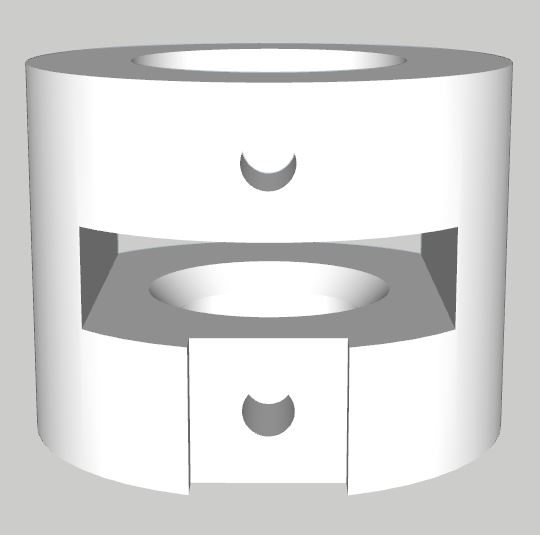

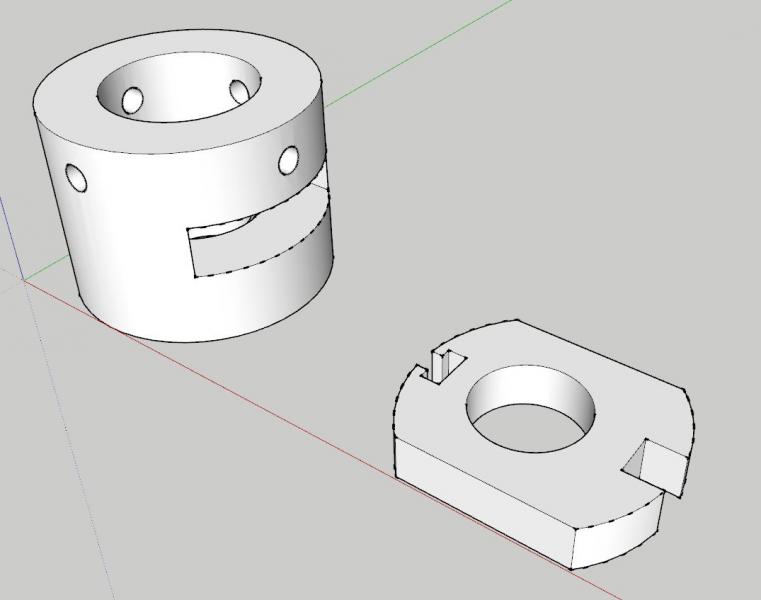

The second reason was that the simple 3-layer catch shown in the animation was not easily fabricated with my sexy Dremel and wasn't strong enough. The result is a big ugly thing but I believe it is an original concept. Imagine the plunger entering from the right, catching on the ring in the middle. The trigger pushes up on the ring, which is bonded to, and flexes up on, a strip of CPVC extending from the CPVC section that is the left end of the catch.

![20151207_175054_HDR.jpg]()

There are a few things I designed that I'm pretty sure are new ideas. Dammit, I give up, I'll just have to get better pictures tomorrow. I haven't updated the model so you won't like it if you see it. Even if I wanted to, my computer is too old to be sexy and can't even install AutoCAD properly.

A few little notes:

-Magazines can be made any length but mine is currently long enough for 14 darts

-Magazines can fit darts up to 1-1/4" in length

-Ranges aren't expected to be impressive, even with a perfect seal. Current stroke is 2-3/4", I believe, which is pathetic, I know. That's just how it is, unless you make the pistol longer.

-I know it's big but it's also smaller than you think.

-Here's a Google Drive folder with all the pictures and videos and maybe the .dwg model file thing.

-Another fitting name for this pistol is Pillow Talk. I was gonna say something gross that rhymes with "eremature pjaculation" but I didn't. Also, it's full unofficial name is Sex Pistol: Experimental Reloading Mechanism.

One more thing. When I was about halfway done building the first crappy prototype that barely held together for a few days, I emailed the guys that print and sell ESLTs and PullSCRTs. They said they'd print any design if you were willing to pay for it. The price they gave me wasn't sexy and they said my model wasn't printable. That's fine, no hard feelings. I had laughs and tears working on this. Thank you guys for not stealing my concept and making it better and printable.

Okay, I'm spent.